Specifications

Time for moving to one pour - 7 min.

Power capacity of travelling mechanisms - 2,2 × 4 kW

Maximum capacity of concurrently working engines - 8.8 kW

Formwork lifting speed - 0.5 m / min

Maximum capacity of the hydraulic power station - 5.5 kW

Lifting height formwork in working position:

- OM1 - 800 mm

- OM2 — 650 mm

Wheelbase

- OM1 — 1400 mm (±60)

- OM2 — 2800 mm (±60)

Length of pour:

- OM1 — 12 m

- OM2 — 3 m

Weight of the unit:

- OM1 — 50 т

- OM2 — 19 т

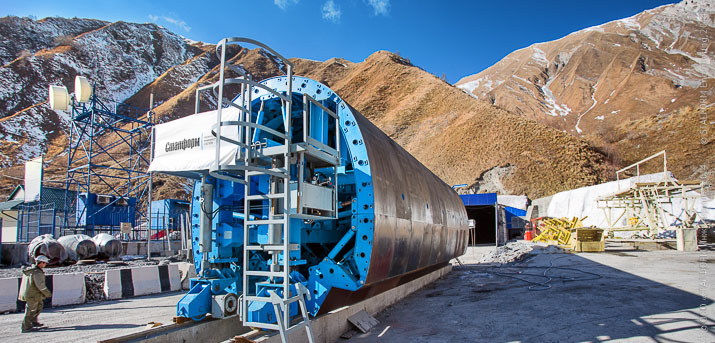

Main components

- The carrier portal, equipped with four individual undercarriage motor-reducers – for moving the formwork along the concreted tunnel. The chassis is equipped with an adjustable wheelbase, allowing placement of the unit in the designed position relative to the track

- Telescopic legs with hydraulic drives - for lifting the formwork into a designed position and stripping

- Shape-forming unit — a pre-engineered assembly-disassembly steel shell design, closely following the contours of concreted tunnel lining. Additional inserts allow concreting of up to 10 different sections of the tunnel by one unit. The shell of the unit is connected to the carrier portal through a system of spindles which are regulating position of the forming sections.

The steel shell is furnished with viewing hatches and provided manholes and slide valves for the connection of the concrete – conveyers, and in the ribs - regular connecting places for the pneumatic vibrators. - The moving mechanism drive — a separate electromechanical drive for each undercarriage.

- The lifting mechanism’s drive — hydraulic, one cylinder per telescopic support. The design provides as synchronous movement of all four telescopic poles, as well as of each individually, allowing more precise setting the formork’s height in accordance with the project

- Scaffolding with enclosure — for work safety