The construction department of the company STALFORM Int is working in 3 directions:

- design and calculation of individual formwork units and mechanisms for application of the formwork systems, which is carried out by the Designing Department the company

- modernization of typical models (inventory) formwork systems of STALFORM

- expansion of the range model STALFORM formwork equipment, protective systems securing safe operation of the formwork

All designing - engineering studies are intellectual product of STALFORM Int and protected by intellectual property laws. All components of the formwork systems and its unit’s components comply with the applicable regulations, furnished by a complete set of design, organizational and technological documentation (passport, instructions) authorizing production and operation of the equipment.

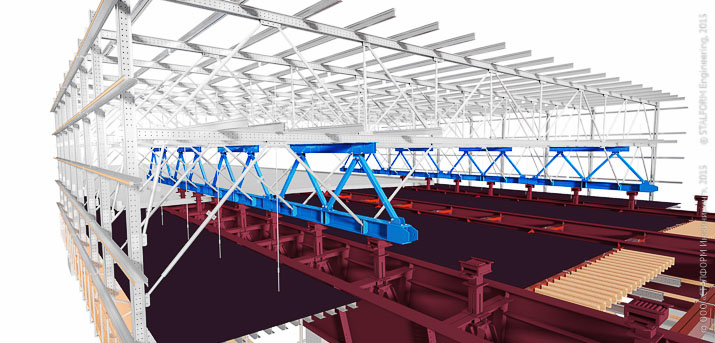

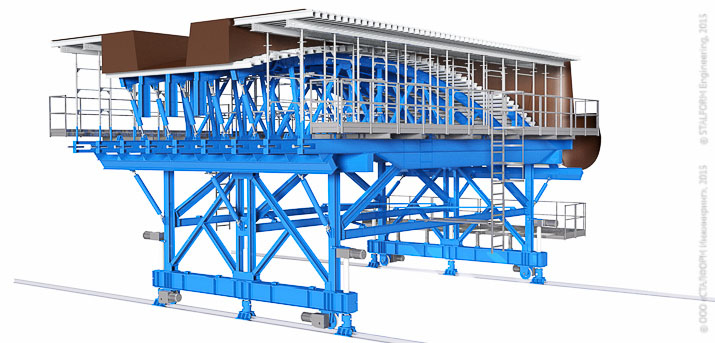

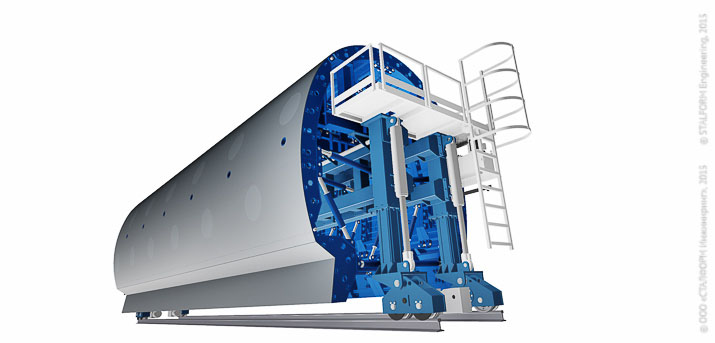

Usage of modern IT-technology (CAD) increases the reliability and quality of design development. Digital 3D-prototypes formwork created in Autodesk Inventor software environment, allows high precision and clarity for modeling and demonstrating to customers the formwork’s erection-stripping processes, with taking into account the loads, stresses, deflections which may be encountered during installation, vibrio-concreting and setting up for the stripping strength.

Principles of construction formwork STALFORM

- Development of know-how — in order to reduce the costs of the formwork and work with it

- Wide range of applications of by a small number of connecting elements

- Introduction of “open system” method: different types of formwork systems are compatible and use standardized components and tooling

- innovation —for improvement of assembling operations

- perfection of the systems striving for increasing its reliability and safety of operation

- Modernisation of formwork systems (provision with hydraulic and electric features) – in order to reduce manual labor, improve speed and performance of work with formwork

Development of new formwork equipment

- specialized formwork for the subway, tunnels, bridges, nuclear power plants and others.

- formwork for special applications (shaper caissons, end supports (caps), breakwaters, etc.).

- mechanized formwork systems and protection systems (re-rolling, self-hoisting)

Introduction of new developments

- Computerized processing of design documentation

- Complete technical training of participants of the production process and design supervision at all stages of the production process - from selection of raw material to acceptance of the finished product

- monitoring compliance of technology and production quality of all parameters of the new equipment to design documentation

- Development of passports, operating instructions and other technical documentation

- participation in the testing assembly of equipment